Now Reading: The Engineering Marvels Behind Spacecraft Heat Shield Technology

-

01

The Engineering Marvels Behind Spacecraft Heat Shield Technology

The Engineering Marvels Behind Spacecraft Heat Shield Technology

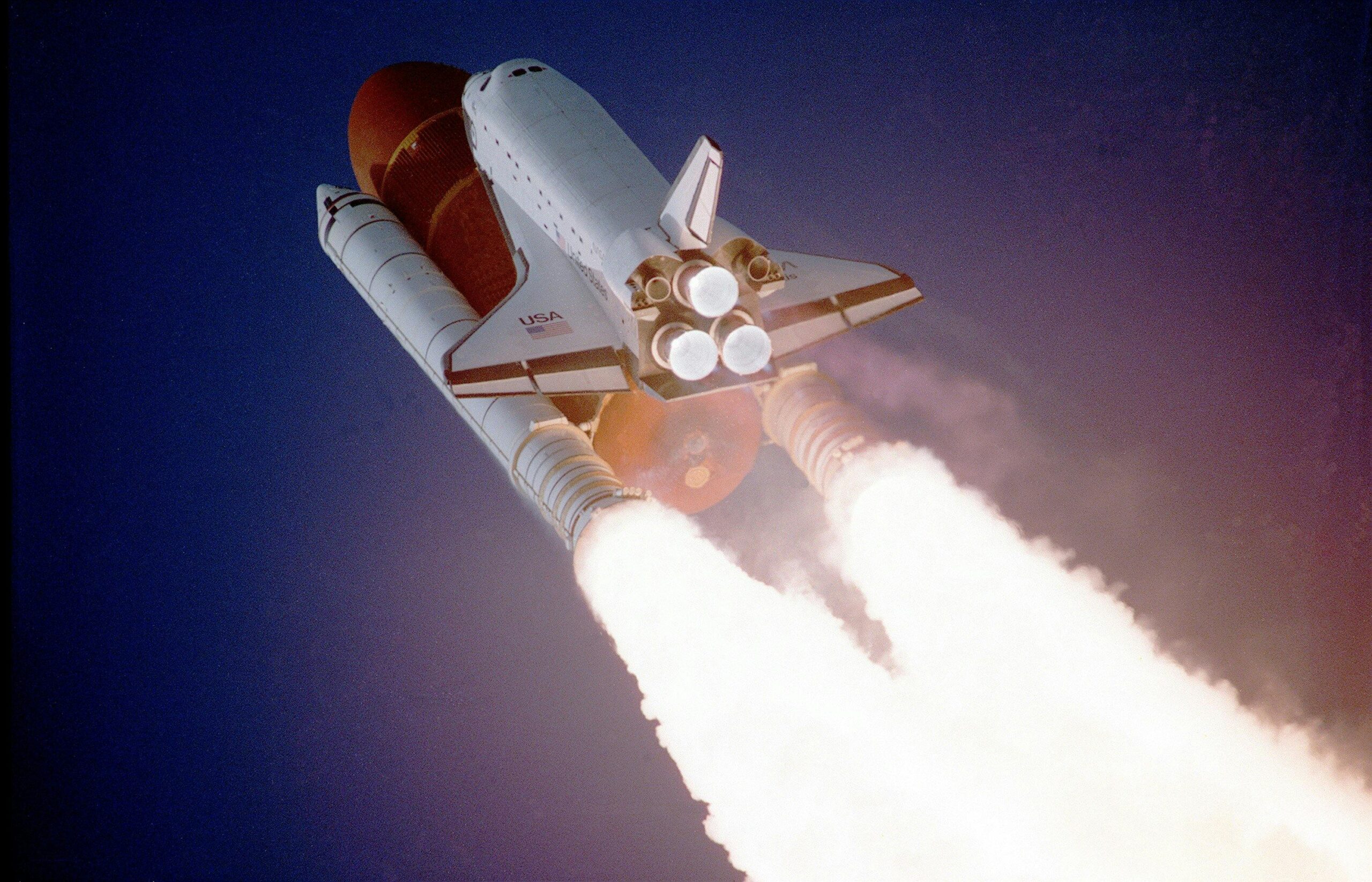

Spacecraft reentry into Earth’s atmosphere is one of the most perilous phases of any space mission. Temperatures can exceed 1,650°C (3,000°F) due to the intense friction between the spacecraft and atmospheric particles. Without proper protection, these temperatures would destroy the vehicle and its occupants or cargo. Heat shield technology is the cornerstone of modern space engineering, enabling safe reentry and inspiring ongoing innovations. From the earliest manned missions of the 20th century to advanced reusable systems today, heat shields represent one of humanity’s most critical space exploration tools.

The Basics of Atmospheric Reentry

As a spacecraft reenters Earth’s atmosphere, it compresses air in front of it, creating a shockwave and generating immense heat. This process, called aerodynamic heating, requires a thermal protection system (TPS) to absorb and dissipate heat, protecting the underlying structure. Heat shields achieve this by using specialized materials designed to withstand high temperatures, resist ablation, or re-radiate heat away from the spacecraft. The type of heat shield depends on the mission requirements, reentry speed, and design constraints.

Types of Heat Shields

- Ablative Heat Shields

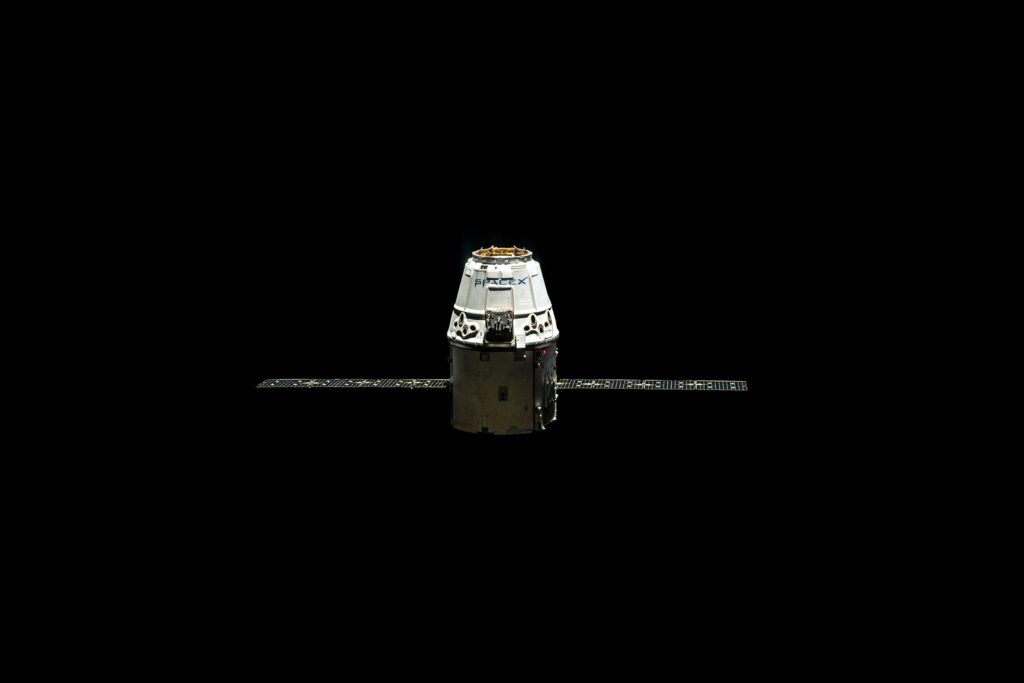

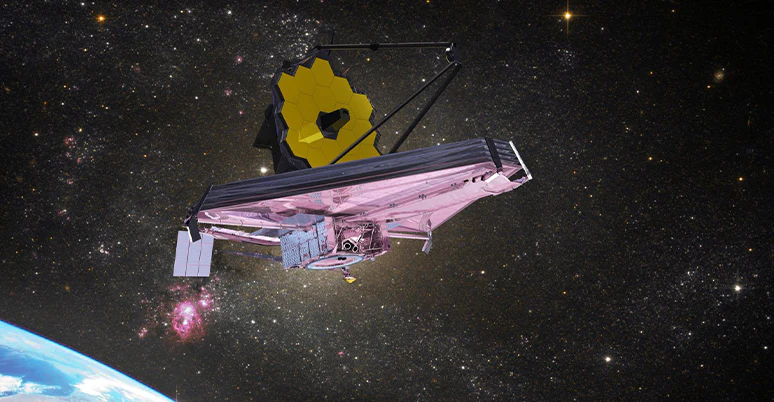

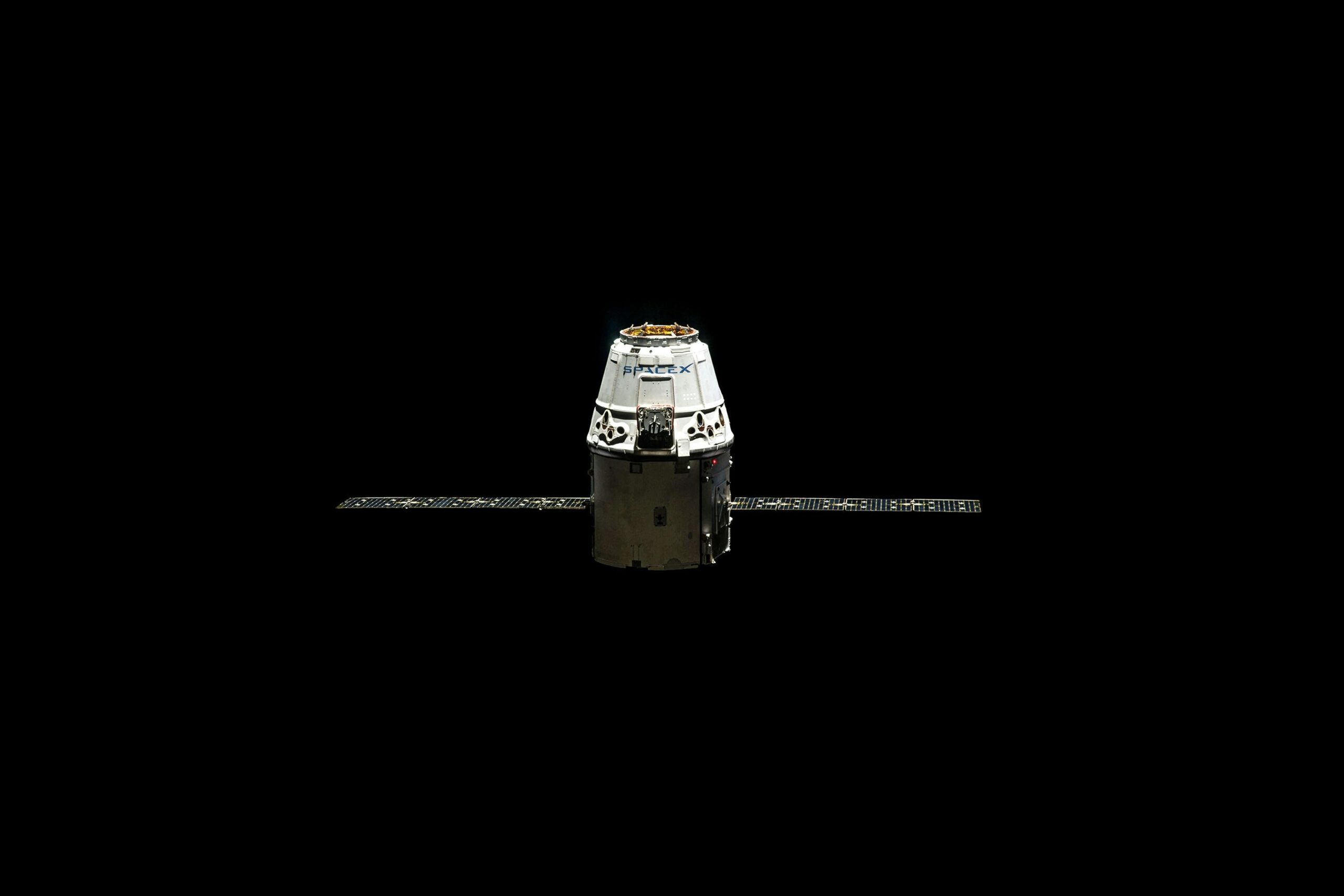

Ablative systems were the first heat shield technology used in space missions. The Apollo spacecraft, which carried astronauts to the Moon, relied on a TPS made of phenolic resin-based materials. Ablation involves the gradual erosion of the material as it absorbs heat, carrying it away as gases (NASA, 2020). Each Apollo mission required a new ablative shield, making this technology expendable but effective.Modern ablative systems have evolved with advanced composites such as Phenolic Impregnated Carbon Ablator (PICA), used on SpaceX’s Dragon spacecraft and NASA’s Mars Science Laboratory. PICA provides superior performance at lower weight, a critical factor in interplanetary missions where payload mass is limited (SpaceX, 2021). - Reusable Heat Shields

The advent of reusable spacecraft, like the Space Shuttle, introduced new engineering challenges. The Shuttle’s TPS combined thousands of silica-based tiles with a lower melting point but exceptional thermal insulation properties (Lichtenberg & Hall, 2019). Each tile could withstand repeated heating cycles, though its fragility made maintenance intensive.SpaceX’s Starship, designed for full reusability, uses stainless steel construction with heat-resistant ceramic tiles only on its windward side. This innovative approach eliminates many challenges faced by previous generations while enhancing durability (Musk, 2019). The high reflectivity of stainless steel also helps radiate heat away, reducing thermal stress. - Heat Shields with Passive and Active Cooling

Advanced concepts for future spacecraft include active cooling systems. Passive systems absorb and redirect heat, while active heat shields would circulate a cooling fluid through microchannels to directly counter thermal loads. Research into metallic TPS and systems that use liquid-based heat rejection is ongoing (ESA, 2021).

Key Engineering Innovations

Heat shield technology relies on a combination of materials science, structural engineering, and computational modeling. Some of the most significant engineering advancements include:

- Multi-layered Insulation (MLI): Used in both heat shields and spacecraft exteriors to reduce heat transfer through radiation. MLI consists of thin layers of reflective material separated by insulating spacers.

- Flexible Ablators: To address the needs of smaller spacecraft, lightweight and flexible ablative materials are under development, offering protection without the bulk of rigid systems (NASA, 2022).

- Predictive Simulation Software: Engineers use computational fluid dynamics (CFD) to simulate heat loads and airflow patterns around spacecraft during reentry, optimizing designs before physical testing.

Challenges and Future Directions

Developing heat shields for next-generation spacecraft involves balancing weight, durability, and reusability. The goal is to create systems that endure multiple reentry cycles without significant degradation. Reusable heat shields are critical for cost-effective space travel, as they reduce the need for expensive refurbishment or replacement.

One promising area of research is carbon-carbon composites, which offer superior performance under extreme heat. These materials were used on the Space Shuttle’s nose cone and wing edges but require further refinement to improve affordability and scalability (Lichtenberg & Hall, 2019). Additionally, deployable heat shields, like NASA’s Hypersonic Inflatable Aerodynamic Decelerator (HIAD), are being developed for missions requiring larger entry vehicles with compact launch profiles.